Commercial laundries in Singapore face mounting pressure to reduce operating costs while meeting increasingly strict environmental regulations. Water recycling technology has emerged as the most effective solution, delivering 45-65% water savings, 15-20% gas reductions, and payback periods as short as 6 months.

This comprehensive guide covers everything you need to know about commercial laundry water recycling in Singapore—from how the technology works to installation, maintenance, ROI calculations, government rebates, and regulatory compliance.

Table of Contents

- 1. What is Commercial Laundry Water Recycling?

- 2. How Does the Technology Work?

- 3. Key Benefits & Cost Savings

- 4. Types of Water Recycling Systems

- 5. ROI & Payback Period Calculations

- 6. Installation Process & Timeline

- 7. Maintenance Requirements

- 8. Government Rebates & Incentives

- 9. How to Select the Right System

What is Commercial Laundry Water Recycling?

Commercial laundry water recycling is an advanced filtration and treatment process that captures, cleans, and reuses water from washing machine rinse cycles. The technology removes lint, detergent residues, dirt particles, and contaminants, producing clean water suitable for reuse in subsequent wash cycles.

The Basic Principle

Modern washing machines use a multi-stage wash process. The initial wash cycles use the most water but also introduce the most contamination. The final rinse cycles use clean water but don't become heavily contaminated. Water recycling systems capture the water from the washing machines, filter it to remove all contaminants, and store it for reuse in the next machine's wash stages.

Who Benefits Most?

High-Volume Facilities:

- • Hotels processing 3+ tonnes/day

- • Hospitals with on-site laundries

- • Aged care facilities

- • Textile rental companies

- • Industrial laundries (20+ t/week)

Cost/Regulation Pressures:

- • High water/sewer costs

- • Water restrictions or scarcity

- • Trade waste discharge limits

- • Sustainability commitments

- • Green certifications

How Does the Technology Work?

Modern water recycling systems use a sophisticated multi-stage filtration process that rivals or exceeds municipal water treatment standards. Here's the complete process breakdown:

5-Step Process Flow

Wash Water

Wash cycle water exits tunnel washer or water extractors

Disc Filtration

Advanced disc filtration removes particles and contaminants

Heat Recovery

Thermal energy in the filtered water captured and reused

Clean Water Return

Filtered warm water returns to washing process at higher temperature

Cloud Monitoring

Continuous performance tracking and predictive maintenance alerts

🔬 Water Quality Standards

The multi-stage filtration process produces water quality that meets or exceeds Singapore standards for commercial laundry reuse. Regular testing ensures consistent quality and washing performance.

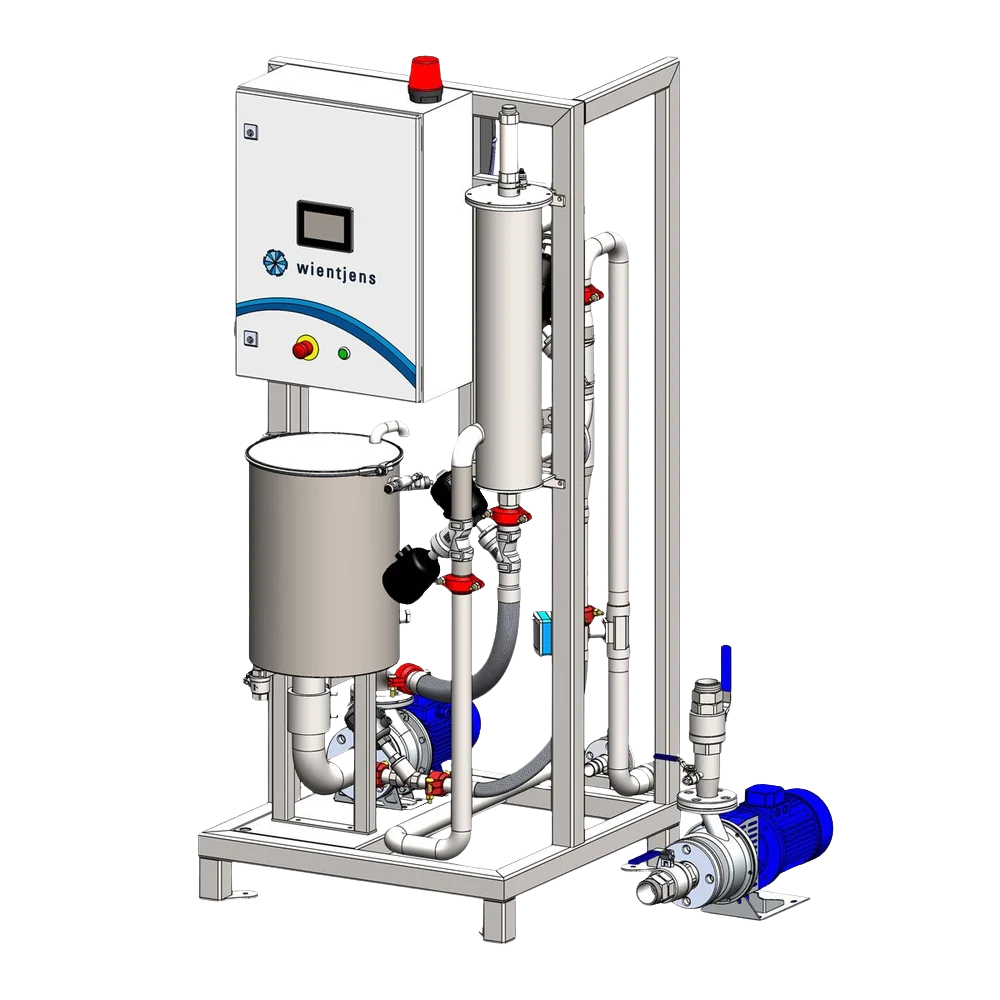

Wientjens Water Recycling Systems

We partner with Wientjens, a leading European manufacturer of commercial laundry water recycling technology. Their modular systems are designed for every size commercial laundry, from compact operations to large-scale industrial facilities. All systems easily retrofit to existing washing machines without equipment replacement.

Blue Ocean

Complete All-in-One System

- • Capacity: Recycles up to 15 m³/hour

- • System: Complete water & energy recycling

- • Features: Integrated buffer tanks, handles fluctuations

- • Installation: Easily adds to existing equipment

Best for: Hotels, hospitals, industrial laundries processing 10 T a day

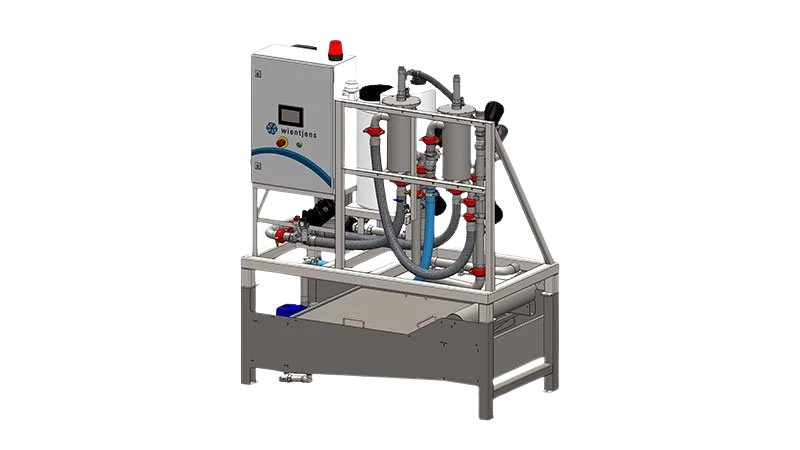

Blue Ocean Compact

Entry-Level Complete System

- • Capacity: Recycles 5 m³/hour (5KL/hour)

- • Volume: Ideal for 20-25 tonnes/week facilities

- • Design: Compact footprint for smaller operations

- • Features: Full water & energy recycling capability

Best for: Boutique hotels, small aged care facilities, regional laundries processing 3-5T a day

AquaMiser

Compact Recycling System

- • Capacity: Up to 12 m³/hour

- • Design: Compact, space-saving footprint

- • Installation: Easy retrofit to existing equipment

- • Benefit: Affordable, fast performance upgrade

Best for: Mid-size operations, aged care facilities, boutique hotels

AquaBatch 3

Batch Wash Water Recycler

- • Capacity: Up to 17 m³/hour

- • Retrofit: Adds to pre-wash, main wash, or rinse zones

- • Filtration: Removes particles, fibers, and hairs

- • Result: Improves wash quality

Best for: Batch washer operations, textile rental, industrial laundries

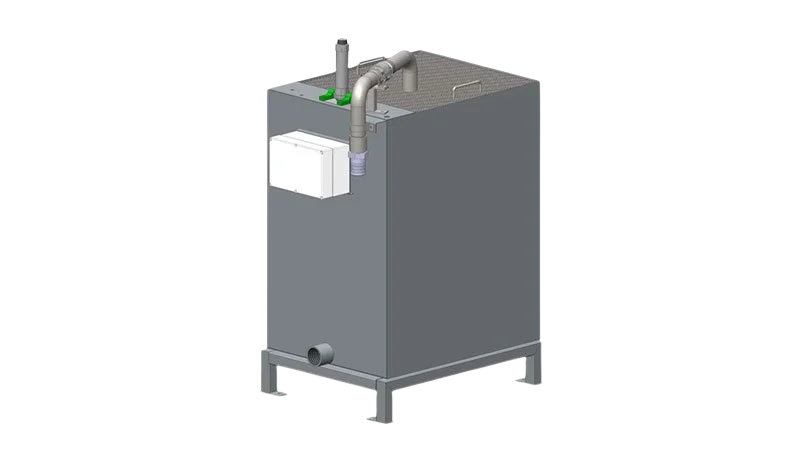

AquaDrain

Backflush Water Filter

- • Function: It captures solid waste from the filtering cycle

- • Benefit: Prevents clogged pipes

- • Impact: Lowers CODs, BODs, suspended solids and microplastics in discharge water

- • Installation: Integrates with existing drainage systems

Best for: All Wientjens filtering systems

💡 Not Sure Which System is Right for You?

Our team will conduct a free water audit of your facility and recommend the optimal Wientjens system based on your laundry volume, space constraints, water quality requirements, and budget. Each system is custom-configured to maximize your water savings and ROI.

ROI & Payback Period Calculations

Understanding your return on investment is crucial for making an informed decision about water recycling. Most commercial laundries see payback periods of 6-24 months depending on facility size and water usage.

ROI Calculation Factors

Water & Sewer Savings:

- • 45-65% reduction in water consumption

- • Equal reduction in trade waste discharge

- • Typical savings: $40K-$300K annually

Energy Savings:

- • 5-20% reduction in gas/heating costs

- • Recycled water retains heat

- • Typical savings: $15K-$80K annually

Chemical Savings:

- • Reduced detergent requirements

- • Lower softening chemical needs

- • Typical savings: $5K-$25K annually

System Costs:

- • Equipment: $80K-$350K

- • Installation: $15K-$60K

- • Annual maintenance: $2K-$5K

💡 Request a Custom ROI Analysis

Every facility is unique. We provide detailed, facility-specific ROI calculations based on your actual water usage, utility rates, and operational patterns. This ensures you have accurate payback projections before making any investment.

Installation Process & Timeline

Professional installation typically takes 5-10 business days from start to finish. Most facilities continue normal operations during installation, with work scheduled during off-peak hours to minimize disruption.

Site Assessment & Design (1-2 weeks)

Our engineers visit your facility to assess water usage, available space, existing equipment, and utility connections. We then design a custom system optimized for your operations.

Equipment Delivery & Preparation (3-5 days)

Equipment arrives on-site and is staged for installation. Our team prepares the installation area, including any required electrical or plumbing modifications.

System Installation (2-4 days)

Physical installation of tanks, filters, pumps, and control systems. Plumbing connections are made to washing machines and existing water supply. Electrical connections completed by certified electricians.

Commissioning & Training (1-2 days)

System startup, testing, and optimization. Your staff receives comprehensive training on operation, monitoring, and basic maintenance procedures.

Blue Ocean Compact & AquaDrain in Action

Installed in a high-volume commercial facility processing 50+ tonnes weekly. Complete setup in just 3 days with minimal space requirements.

Wientjens Blue Ocean Compact system

Maintenance Requirements

Modern water recycling systems are designed for minimal maintenance. Proper upkeep ensures optimal performance, maximizes water savings, and extends system lifespan to 15-20 years.

💡 Annual Maintenance Costs

Total annual maintenance costs typically range from $2,000-$5,000, including quarterly professional service. This represents less than 2-3% of annual savings, making water recycling extremely cost-effective over the system's 15-20 year lifespan.

Government Rebates & Incentives

Various government incentive programs may be available to help reduce the upfront cost of water recycling systems. These programs vary by state and change regularly.

💡 Our Partners Help You Find Available Rebates

Our installation partners will identify what rebates and incentives are currently available in your area during the site assessment.

How to Select the Right System

Get a Professional Assessment

Every facility is unique. We provide free on-site assessments to recommend the optimal system configuration for your specific needs, ensuring maximum water savings and fastest ROI.

Frequently Asked Questions

What ROI and savings can Singapore commercial laundries expect with water recycling, and why is Singapore exceptional?

How does Singapore's ROI compare globally, and why does it keep improving?

What certifications and compliance standards apply to commercial laundry water recycling in Singapore?

Which Singapore commercial facilities benefit most from water recycling?

What is the installation timeline for water recycling systems in Singapore?

What are the ongoing maintenance requirements and costs for water recycling systems in Singapore?

Are there government incentives available for water recycling in Singapore?

Is recycled water safe for healthcare, hospitality, and aged care laundry in Singapore?

What is the Blue Ocean water recycling system and why is it ideal for Singapore facilities?

Ready to Calculate Your Savings?

Get a free ROI analysis and custom water recycling proposal for your facility